|

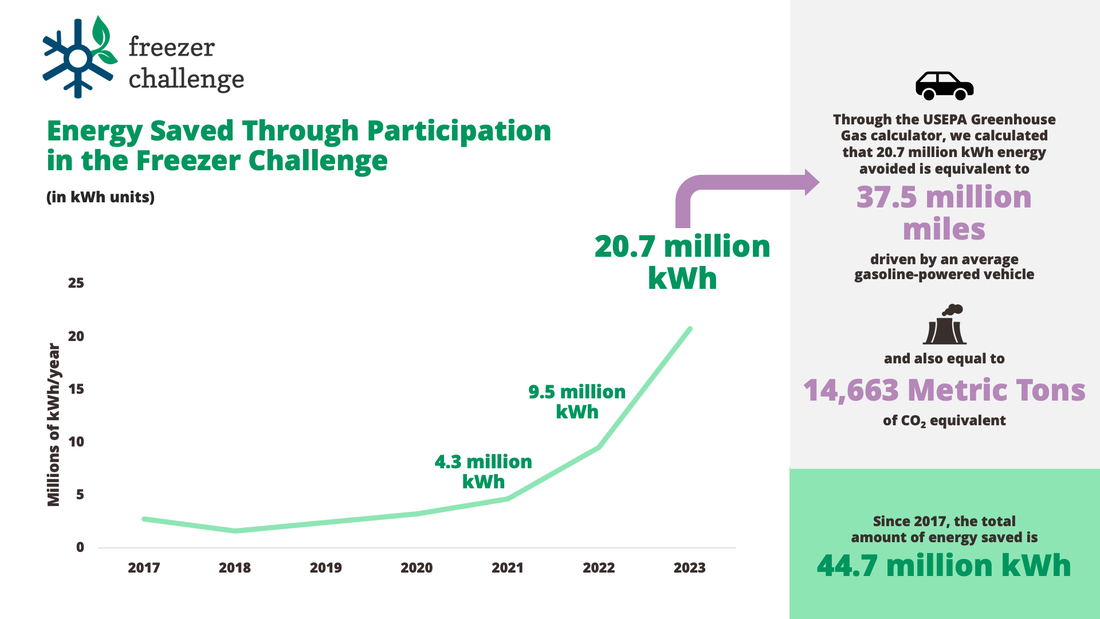

In 2023, My Green Lab and the broader green lab community achieved notable milestones, bringing sustainability to the forefront of the scientific community. From unprecedented program expansions to launching a global collective supply chain initiative, My Green Lab’s mission and momentum continues to grow; supported by a powerful and dedicated community of green lab leaders around the world. As we pause to reflect on the progress made in 2023, it's clear that this collaborative spirit and partnership with the My Green Lab community has propelled us forward. Our shared mission of promoting sustainability in science has grown thanks to the dedication of our community members, forward-thinking sponsors, partners, and collaborators. Thank you to everyone who has helped and continues to champion our mission of building a global culture of sustainability in science. Below are our top ten highlights and milestones that defined My Green Lab's journey in 2023, shaping the narrative of sustainable science for the years ahead. 1: My Green Lab Unveiled Converge, a Collaborative Supply Chain Initiative Harnessing the collective efforts of pharmaceutical and biotechnology companies, our team was proud to launch Converge, a collaborative supply chain initiative, at COP28 in December 2023. In collaboration with founding sponsors AstraZeneca, GSK, Bristol Myers Squibb, Amgen, and Merck KGaA, this initiative encourages suppliers like Contract Research Organizations (CROs), Contract Manufacturing Organizations (CMOs), and Contract Development and Manufacturing Organizations (CDMOs) to reduce the environmental impact of labs in their value chain through My Green Lab Certification. Converge is a major turning point in the uptake of green labs globally and in achieving the UN-Backed Race to Zero Breakthrough Outcome goal that 95% of all labs are My Green Lab Certified by 2030. 2: The 2023 Carbon Impact of Biotech & Pharma Report In December, we released the 2023 update to our Carbon Impact of Biotech & Pharma Report which provides an overview of the industry’s carbon footprint and identifies key opportunities for change. The report found an increase in the industry’s Race to Zero commitments, with thirty-five companies, or 53% of the sector by revenue, committing to the Race to Zero, up from thirty companies last year. Along with tracking notable progress within the industry, the report also highlighted the need for increased action in scope 3 reductions and collaborative supply chain engagement. 3: My Green Lab Accredited Professional (AP) Program Certifies Over 60 Green Lab Experts All six modules of the world’s first green lab accredited professional program became available on mygreenlab.education in October, and over 60 individuals have since become accredited green lab experts through the program. With modules on Energy, Water, Engagement, Procurement, Green Chemistry, and Waste, the AP program provides a comprehensive, holistic education on achieving sustainability in the lab and beyond. Our program aims to empower the scientific community to make better-informed choices in order to collectively contribute to a more environmentally conscious and responsible global research landscape. 4: My Green Lab Certification Engaged 2,000+ Labs and 26,000+ Scientists from 45 Countries In November, My Green Lab Certification hit a remarkable milestone by reaching 2,000+ labs across 45 countries, bringing green lab best practices to over 26,000 scientists. The global success of this program, considered the gold standard for laboratory sustainability and the cornerstone of our mission, highlights the scientific community’s commitment to making real, impactful environmental changes within their laboratories. 5: The ACT-Eco Label Program reached 2,540 Labels Another significant achievement in 2023 was the ACT-Eco Label Program attaining a milestone of 2,540 labels! Labs demand substantial resources, and the products used contribute greatly to their environmental impact. The ACT-Eco Label program simplifies the process of selecting more sustainable products by providing third-party verified information about the impact of a product. Along with My Green Lab Certification, the ACT-Eco Label is one part of a community working to drive real change within labs. 6: The 2023 Freezer Challenge Saved 20.7 Million kWh of Energy Since its launch in 2017 by My Green Lab and I2SL, the International Laboratory Freezer Challenge has experienced substantial growth, with the 2023 challenge marking its most successful year to date. Participating labs contributed to saving a whopping 20.7 million kWh of energy, corresponding to 14,663 metric tons of carbon dioxide equivalent. The challenge doubled the amount of CO2 saved in 2022, with nearly 2,000 laboratories around the world participating in the free competition that promotes energy efficiency through best practices in cold storage management. We are sure that 2024 will be another year of record-breaking success for this important green lab program. 7: AstraZeneca’s Penny James Joined the My Green Lab Board of Directors My Green Lab was proud to announce the appointment of Penny James to its Board of Directors in 2023. As Chief Operating Officer in R&D BioPharmaceuticals at AstraZeneca, Penny brings extensive experience and a 30-year career marked by impactful leadership to the My Green Lab Board. We are honored and excited to have Penny on the team and look forward to her contributions to helping build a global culture of sustainability in science. 8: My Green Lab and Science Foundation Ireland launched a Sustainable Laboratory Certification Pilot Program Science Foundation Ireland (SFI) launched a program for the widespread rollout of My Green Lab Certification across all eligible, SFI-funded labs in 2023, creating the first nationwide sustainable lab program of its kind. In collaboration with My Green Lab, this program promises to reshape the landscape of lab sustainability in Ireland and around the world. A global first, this partnership will extend the reach of My Green Lab Certification and inspire other national and international foundations to invest in sustainability. 9: My Green Lab Sponsors Support Sustainable Science Our growth in 2023 was made possible by our community of generous sponsors. We extend our heartfelt gratitude to these sponsors, whose unwavering support continues to play a pivotal role in bringing our mission to life. It is through their commitment that we can expand our initiatives, promote sustainable practices, and make a lasting impact on the scientific community. 10: My Green Lab’s Team: Continued Growth and Commitment to Sustainable Science This year’s progress and growth wouldn’t have been attainable without the invaluable support and collaboration of the exceptional team at My Green Lab. As the momentum of our mission grew, so did our team – with four new additions strengthening our presence as an organization. Thank you to our team for their continued dedication to building a global culture of sustainability in science. In gratitude, James Connelly Chief Executive Officer, My Green Lab Penny James, BioPharmaceuticals R&D Chief Operating Officer at AstraZeneca, Brings Three Decades of Expertise to Strengthen My Green Lab's Commitment to Sustainable Science My Green Lab is proud to announce the appointment of Penny James to its Board of Directors. As Chief Operating Officer in R&D BioPharmaceuticals at AstraZeneca, Penny’s extensive experience in the pharmaceutical and chemical industries will help My Green Lab continue to build a global culture of sustainability in science.

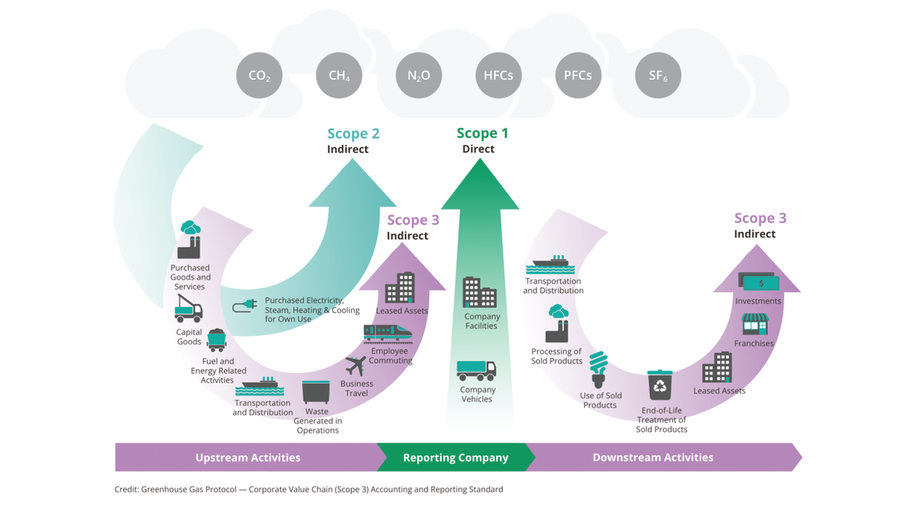

"We are thrilled to welcome Penny James to the My Green Lab Board of Directors. Penny's wealth of experience at AstraZeneca, coupled with her deep commitment to sustainability and her leadership capabilities, align perfectly with My Green Lab's mission. Her strategic vision and extensive background in driving process efficiency will undoubtedly enrich our organization as we continue to advance sustainability practices in laboratories worldwide,” said James Connelly, CEO, My Green Lab. “Penny's dedication to environmental stewardship will be a valuable asset as we work towards a greener and more sustainable future for the scientific community.” With a 30 year career marked by impactful leadership, Penny assumed the role of COO BioPharma R&D at AstraZeneca in 2019, following her tenure as Vice President Operations for the IMED Biotech Unit. She has played a pivotal role in driving process efficiency and effectiveness, leading Lean Sigma programs across Europe and the US at the Eastman Chemical company. Penny also holds positions on the boards of Cambridge Biomedical Campus Ltd, One Nucleus, and the MRC Environmental Sustainability Council. With a Master’s in Medical Statistics and as a Chartered Statistician and Lean Sigma Master Black Belt, Penny is well-equipped to contribute significantly to My Green Lab's mission and initiatives. "I am delighted to join the My Green Lab Board of Directors. Having worked closely with the organization to bring sustainability best practice to AstraZeneca’s R&D laboratories, I believe in their commitment to advancing sustainability across the scientific community. I am eager to contribute to My Green Lab's impactful initiatives and collaborate with fellow board members to drive further positive change. Together, we will champion sustainable practices that make a meaningful difference in laboratories around the world,” said Penny. Recognized as one of the most sustainable biopharmaceutical companies, AstraZeneca understands the importance of bringing a culture of sustainability to science and beyond. Collaborating closely with My Green Lab, they have undertaken key initiatives that showcase their commitment to protecting the environment. This partnership includes AstraZeneca’s active participation in the International Freezer Challenge, a program that has saved over 44 million kWh of energy in laboratories across the globe since 2017. Through Penny’s leadership, AstraZeneca has also achieved My Green Lab Certification for all its R&D lab facilities, a program that is considered the gold standard for laboratory sustainability best practices around the world. In partnership with My Green Lab, AstraZeneca is leading the charge for sustainable science, establishing standards that facilitate the creation and distribution of new medicines in the most environmentally responsible manner possible. Founding Sponsors AstraZeneca, GSK, Bristol Myers Squibb, and Amgen Join Forces with My Green Lab to Drive Sustainable Practices Across the Industry My Green Lab, the world’s leading nonprofit organization dedicated to improving the sustainability of scientific research, today announces the launch of Converge, a collaborative supply chain initiative. With a shared goal of supporting lab sustainability, founding sponsors of the initiative include AstraZeneca, GSK, Bristol Myers Squibb, and Amgen. Pharmaceutical companies rely on their suppliers to provide goods and services and represent Scope 3 carbon emissions in their value chain. Supplier engagement with Contract Research Organizations (CROs), Contract Manufacturing Organizations (CMOs), and Contract Development and Manufacturing Organizations (CDMOs) is important to address Scope 3 carbon emissions. Converge will leverage the collective and collaborative efforts of pharmaceutical and biotechnology companies to encourage suppliers with a large research footprint to reduce the environmental impact of their labs through My Green Lab Certification, a key indicator of progress for the United Nations Climate Change's High-Level Climate Champions 2030 Breakthroughs Race to Zero campaign. Pharmaceutical and biotechnology companies with ten or more labs already enrolled in My Green Lab Certification are encouraged to sign up and join a collective initiation aiming to certify all labs across the value chain in alignment with the Race to Zero’s breakthrough outcome that 95% of all labs are My Green Lab certified at the highest level by 2030. Through Converge, suppliers will be provided with additional resources and peer-to-peer learning that will support increased scientist awareness and engagement in sustainability measures, alongside cost reductions through lowered energy, water, and waste supported by additional resources and peer-to-peer learning. The program’s partners gain secure access to a Supplier Dashboard for tracking green lab certification progress, and an Impact Estimator tool for measuring environmental reductions. The initiative also offers its participants educational webinars and a Supplier Network Group for peer-learning facilitated by My Green Lab. “Suppliers play a vital role in the industry and based on our 2022 Carbon Impact Report, the majority of the impact comes from the value chain. When suppliers partner with My Green Lab through Converge and earn My Green Lab Certifications, they are not only actively supporting lab sustainability, but also solidifying their position as a trusted and preferred organization in the industry,” says James Connelly, My Green Lab’s CEO. About My Green Lab Certification

My Green Lab Certification provides actionable ways for scientists and laboratory teams to make meaningful changes within their daily operations. It is considered the gold standard for laboratory sustainability best practices around the world and has helped over 2,000 labs in 45 countries and over 26,000 scientists preserve resources, save money, and ensure a safe and healthy environment in support of science. About Converge Converge envisions a comprehensive dedication to lab sustainability throughout the pharmaceutical industry. Converge aims to ensure every supplier lab has a thriving culture of sustainability and every scientist knows how their actions can make a difference. Converge will help the pharmaceutical sector lead the world on supply chain engagement and inspire other sectors to follow in its footsteps. This report released during COP28 shows an increase in the sector's Race to Zero commitments while highlighting the need for increased action in scope 3 reductions and collaborative supply chain engagement The Biotech and Pharma industry is a significant contributor to global climate change, and therefore must be part of the global climate solution. The global biotechnology market size was estimated at USD $1.0 trillion in 2021 and is expected to grow at a compound annual growth rate (CAGR) of 13.9% from 2022 to 2030, reaching $3.9 trillion by 2030. A report produced by My Green Lab with contribution from Intercontinental Exchange (ICE) found significant progress towards the adoption of net-zero goals within the Biotech and Pharma sector, with more companies joining the UN-backed Race to Zero initiative, and some notable successes in the largest companies making year-on-year intensity reductions. The report was released during COP28 on Dec 5, 2023, and showed that the pace of accomplishments, while substantial, must be greatly accelerated for the industry to remain below the 1.5˚C threshold that the UN’s Intergovernmental Panel on Climate Change (IPCC) warns our planet should not cross. As of 2023, thirty-five companies (53% of the sector by revenue) have committed to the Race to Zero initiative, an increase from 30 companies (46% by revenue) at this time last year. Progress towards the Breakthrough Outcome has also been swift, with 63% of Pharma and Med Tech companies in the campaign having started a My Green Lab Certification, and nearly half of those programs at a global scale. Key Findings of the Report The report is an update to My Green Lab's 2021 & 2022 reports, which was the first to evaluate the upstream and downstream value chain of Biotech and Pharma by quantifying Scope 3 emissions for both public and private companies. The report leverages data from 226 publicly-listed companies and 147 privately-held companies to produce a comprehensive profile of the carbon emissions of the Biotech and Pharma industry, including a comparison of this emissions profile to other industry sectors. The analysis also identifies critical hotspots that are opportunities for positive change while charting industry progress towards the UNFCCC Race to Zero and the UNFCCC 2030 Breakthrough Outcomes campaign. One of the results of the report is that 90% of the 91 public companies analyzed in the sector still do not have targets (for Scope 1 and 2) in the short term (2021–2025) that are aligned with a 1.5˚C increase world. It also found that the overall carbon impact of the industry has been rising every year, going from 3.9% in 2021 to 5% in 2022. Another key finding of the report is that Scope 3 emissions are 4.6-fold Scope 1 and 2 combined, with the vast majority of Scope 3 emissions coming from purchased goods and services. In response, the industry has launched a suite of collective initiatives that show great promise in reducing Scope 3. Collaborative Efforts and Industry Alliances In 2021, My Green Lab’s flagship program, the My Green Lab Certification was selected as a Race to Zero Breakthrough Outcome to help pharmaceutical and medical tech companies achieve the goal of a zero-carbon world by 2050. It focuses on reducing emissions for Scope 1 and 2 by making laboratory operations more sustainable. It further helps catalyze Scope 3 reductions by encouraging sustainable purchasing within organizations and with laboratories that a company contracts within its supply chain. To meet the targets of the Paris Climate Agreement, the industry must continue to improve the quality and comparability of reporting, while taking rapid and measurable actions on industry carbon footprints and engaging the industry supply chain. Harmonization of supplier requirements by the Sustainable Markets Initiative and forums such as the Pharmaceutical Supply Chain Initiative are helping to create industry alignment. To tackle the challenge of addressing Scope 3, the industry has launched a suite of programs to align requests and help support suppliers in accomplishing these supply chain goals. An example of such an initiative is My Green Lab’s Converge program, which is expected to have a powerful impact on suppliers with great potential for rapid and effective action. Converge, My Green Lab’s Supplier Initiative Converge is a My Green Lab initiative that aims to harness the collective power of the Pharmaceutical industry to encourage suppliers to reduce the impact of their operational labs through My Green Lab Certification. The program enrolls large Pharma companies that have at least 10 labs enrolled in My Green Lab Certification and requires them to collectively request that suppliers including Contract Research Organizations (CROs), Contract Manufacturing Organizations (CMOs), and Contract Development and Manufacturing Organizations (CDMOs) with significant laboratory operations certify their labs in alignment with the 2030 Breakthrough Outcomes target. The target is for 95% of all labs to be certified at the highest level. In November 2023, four major Pharma companies, AstraZeneca, GSK, Amgen, and Bristol Myers Squib joined the Converge initiative. They outlined the targets seen in the following figure for their joint suppliers. Conclusion

Biotech and pharmaceutical companies have the technical acumen, culture of innovation, and financial resources needed to be a global leader in environmental sustainability. They also have a shared supply chain and collaborative industry organizations necessary to align requirements and support collective action. The industry has just under a decade, roughly the same time it takes to bring a new drug to market, to achieve net zero carbon and, in doing so, inspire industry sectors around the world. How My Green Lab’s ACT Eco Label Program is Transforming Laboratory Products and Purchasing11/21/2023

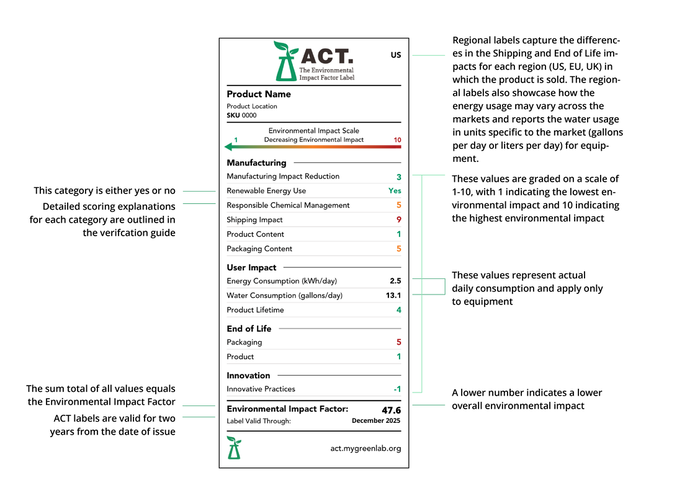

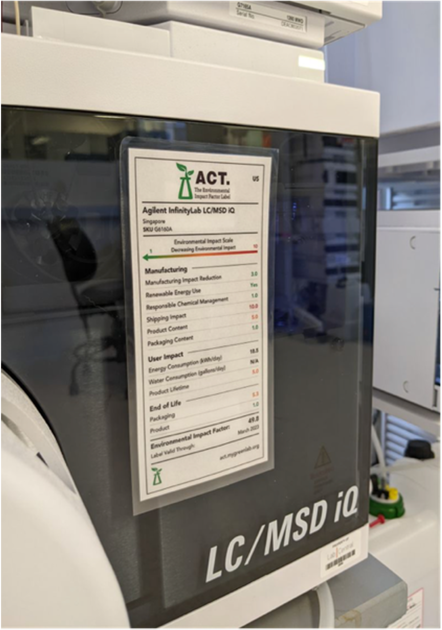

As most scientists and lab experts would agree, laboratories demand substantial resources and have a considerable ecological footprint. To put it in perspective, labs generate an astonishing 12 billion pounds (5.5 billion kg) of plastic waste annually and consume ten times the energy and four times the water compared to typical office spaces. Amidst this impact, there is a pressing need for innovative solutions to mitigate the environmental consequences. The products used in laboratories greatly contribute to this environmental impact, emphasizing the urgency for sustainable alternatives in lab practices and materials. In an effort to improve their environmental footprint, scientists and procurement specialists are actively seeking a solution to support making smarter and more sustainable purchases, achieve their environmental goals, and meet carbon commitments. The Solution: The ACT Environmental Impact Factor Label. To transform sustainability in the laboratory product market, the groundbreaking ACT Eco Label Program from My Green Lab provides third-party verified information about the environmental impact of laboratory products. This independent analysis supports product Accountability, Consistency, and Transparency (ACT), allowing manufacturers to effectively communicate the sustainability attributes and impacts of their products and support smarter, more informed purchases by laboratories. With an ACT Eco Label, manufacturers demonstrate accountability for the environmental impact of their product and their dedication to reducing that impact. An ACT-labeled product also demonstrates a manufacturer's willingness to evaluate products with a consistent, industry-standardized method, and to transparently provide details of the product’s materials, manufacturing process, recyclability, energy and water consumption, durability, and manufacturing location. The ACT Eco Label clearly and effectively simplifies the process of selecting more sustainable products. The ACT Eco Label Evaluation Categories To provide in-depth, verified, and useful information, the ACT Eco Label Program evaluation process looks at all aspects of a product’s life cycle, measuring a variety of criteria that results in the most comprehensive eco label for life science products. Like a Nutrition Facts Label for laboratory products, the ACT Eco Label communicates the complex environmental impact information for a product in an easy-to-understand format. Criteria for the ACT Eco Label were developed by industry experts including scientists, sustainability experts, procurement specialists, and manufacturers. Environmental Impact Factor (EIF) criteria in the ACT Eco Label fall into a variety of categories that are evaluated during the auditing process, including:

Each of the impact factors described here contributes to the environmental footprint of the product. By auditing and evaluating these product attributes to the ACT Eco Label Standard, My Green Lab helps manufacturers consider, measure, and drive continuous improvement in these factors, resulting in companies providing more sustainable products for laboratories. Independent auditor SMS Collaborative (SMSC) has extensive experience evaluating products to the ACT Eco Label Standard, a process that provides clear, third-party verified information about the environmental impact of laboratory products. The ACT Eco Label’s Impact on the Laboratory Product Market The ACT Eco Label Program incentivizes manufacturers to present information about their products in a transparent way, and to highlight innovations in sustainability. All ACT-labeled products are categorized by general product type (Consumables, Equipment, and Chemicals & Reagents) on the ACT Eco Label database, which is fully searchable and filterable. It allows laboratories to compare products before purchasing, and to evaluate the impact of products currently in use, by assessing the product scores overall and in each EIF category. The database can also be integrated into procurement databases, helping drive the adoption of more environmentally-friendly lab products at the point of purchase. For example, ACT Eco Labels are now fully searchable on the CiteAb reagent search engine, and are used by the Fisher Scientific database to identify greener products. The impact that the ACT Eco Label program has on transparency in the lab product market is wide-ranging, with over 1,000 products in the ACT Eco Label database from 24 large and small manufacturers (as of November 2023). “The growth of the program highlights how important transparency is in the marketplace. As the market seeks to become more engaged when it comes to product sustainability, and lab sustainability as a whole, laboratories are helping drive the need for programs like ACT by encouraging more sustainable, third-party verified products from their suppliers,” says Raj Patey, My Green Lab’s Business Development Director. “The program’s growth is not only resulting in more transparency in the market, but also in genuine product improvement. For example, some manufacturers are learning from the product audit process and subsequently making changes to their product’s packaging or manufacturing in ways they otherwise wouldn't have done without the guidance of the ACT Eco Label Program,” Patey noted. ACT in Action Demonstrating the industry’s united effort towards driving more sustainable practices, My Green Lab has partnered and worked with a variety of organizations that support the ACT Eco Label Program, including companies that label their products, and groups that use the database to find sustainable product solutions for their lab. Thermo Fisher Scientific has one of the largest ACT-labeled product portfolios, with a wide variety of products, from Ultra-Low Temperature (ULT) freezers to beakers and cylinders. “ACT-labeling our portfolio helped us understand the myriad ways our products can help our customers achieve their sustainability goals. Plus, we can point customers to the ACT Eco Label database for scores and provide helpful insights to how the scores were generated – both of which will allow customers to make informed decisions when purchasing equipment,” Thermo Fisher Scientific told My Green Lab. Bürkle GmbH recently introduced ACT Eco Labels for their LaboPlast® Bio and SteriPlast® Bio disposable samplers, featuring sugarcane-based bioplastic. “The T in the ACT [Eco] Label stands for Transparency. Transparency is a fundamental value that guides our every step. We believe that openness fosters understanding, and understanding builds trust,” Bürkle GmbH posted recently on LinkedIn. “To ensure more transparency, we have decided to have our products certified with the ACT [Eco] Label. Transparency isn't always about showcasing perfection; it's about admitting when we're learning, evolving, or finding new ways.” Eppendorf has been in partnership with My Green Lab since 2017 and has a wide variety of products in the ACT Eco Label database, including the first centrifuge on the market to achieve sustainability recognition through the ACT Eco Label Program. “The ACT Program is… the only global program for laboratory equipment which addresses sustainability aspects and product life aspects. In 2017, we were just a very small group of suppliers supporting My Green Lab. Today, most of the bigger suppliers of lab equipment participate and label products by ACT. On the customer side, many pharma accounts are asking for ACT-labeled products, and also academic accounts are interested,” Eppendorf recently told BioProcess International.

Better Products for a Better Future My Green Lab’s work reaches a global audience through education and collaboration with laboratories that want to bring sustainability to science. The ACT Eco Label is one part of a community working to drive real change within laboratories. Through programs such as My Green Lab Certification and the Ambassador Program, the My Green Lab team continues to engage closely with laboratory communities. This work with scientists and lab professionals has illuminated a compelling need for clear, standardized information about laboratory products. It is well-recognized that a significant part of the carbon impact from a lab originates from the lab products they purchase and use. At its core, the ACT Eco Label program empowers scientists and procurement specialists to make well-informed decisions with sustainability goals top of mind. The ACT Eco Label Program began as a consensus-based effort between manufacturers, procurement, sustainability professionals, and scientists who were deeply committed to improving the trajectory of sustainability in science. My Green Lab is now engaging with stakeholders throughout academia, sustainability, biotech, and pharma to guide revisions in the ACT Eco Label Program. This process will further support the uptake of the program across the entire industry, incorporate more product data for customer and manufacturer awareness, and continue to make choosing preferred lab products easier while updating the functionality of the database. As our process improves, we passionately believe that starting your sustainability journey with the ACT Eco Label not only steers you towards enhanced customer engagement and reduced product impact over time, but also contributes to creating a better future. |

Sign Up for Our Newsletter! |

Contact UsCopyright 2013-2024 My Green Lab®, all rights reserved.

About My Green LabMy Green Lab® is a 501c3 non-profit organization.

All gifts are tax deductible in accordance with IRS regulations. |