|

Co-written by My Green Lab and Triumvirate Environmental At My Green Lab, we understand the unique challenges laboratories face in their journey towards sustainability. One of our goals is to bridge the gap between ambitious sustainability goals and practical, achievable steps that labs can take. We offer a variety of programs designed to make labs greener, such as the My Green Lab Certification program, ACT Eco-Label for sustainable product evaluation, and the International Laboratory Freezer Challenge. These initiatives not only help labs reduce their environmental footprint, but also enhance efficiency and promote a culture of sustainability within the scientific community.

However, sustainability in laboratories isn't just about reducing waste or energy consumption; it’s about creating a holistic approach that integrates environmental responsibility into every aspect of laboratory operations. This includes everything from procurement of sustainable products, efficient energy use, waste minimization, and promoting a culture of sustainability among staff. By adopting comprehensive sustainability practices, labs can significantly reduce their environmental impact while often realizing cost savings and operational efficiencies. Environmental partners can be key to achieving these goals. They bring specialized knowledge and practical solutions that can help labs implement and maintain effective sustainability practices. A competent and capable partner can provide critical support in navigating EHS regulations, optimizing resources, and ensuring efficiency in ongoing progress. In addition, partnerships foster innovation and creativity, enabling labs to tackle sustainability challenges with confidence—all while achieving meaningful results. Why You May Need an Environmental Partner Navigating the complex landscape of environmental regulations and sustainability best practices can be challenging. An environmental partner can provide the expert guidance to help ensure your lab stays compliant with the latest sustainability standards—as well as optimize resource use, meaning cost savings and reduced environmental impact. By offering specialized services such as waste management, environmental leadership, and consulting for such topics as energy efficiency solutions or best practice implementation, environmental partners can address the sustainability challenges unique to your laboratory and help you move forward in a knowledgeable and effective way. Moreover, a trusted environmental partner will support sustainability initiative implementation, ensuring a smooth transition into new procedures and practical outcomes of these changes. Continuous improvement is another benefit of partnering for sustainability services; an environmental partner can help track progress and measure impact, spurring sustainability practice evolution and success over time. Almost every facility requires some form of support in implementing sustainability initiatives—rarely can an organization operate completely independently in this venture. Be it with green waste disposal, environmental consulting, or sustainable committee leadership, there are almost always some major tasks that warrant sustainability services from a competent and experienced partner. Some signs that your organization may need help from an environmental partner are:

If one or more of these apply to you, it might be time to consider working with an experienced and dedicated environmental partner who can guide and support your sustainability journey. EHS Partnering for Lab Sustainability At My Green Lab, we provide the framework and tools necessary to help labs achieve their sustainability goals. Our My Green Lab Certification program sets the standard for best practices in lab sustainability, covering areas such as energy conservation, waste reduction, and sustainable purchasing. Labs that achieve this certification demonstrate a commitment to sustainability and leadership in the scientific community. While our programs provide the framework and recognition for sustainable practices, an environmental partner can offer the on-the-ground support necessary for implementing these practices. EHS vendors like My Green Lab’s Accelerator Partner Triumvirate Environmental can support your lab's journey towards sustainability. With a deep-set commitment to sustainability and an expansive set of service offerings, including sustainable waste management, from upstream waste management to downstream recycling and other green disposal, Triumvirate Environmental has the know-how—and the onsite support—to help you succeed. Whether you seek guidance on best practices, insights into broader organizational initiatives, leadership for your sustainability committee to drive innovation and success, or physical waste and onsite services, Triumvirate Environmental, with over 65 My Green Lab Ambassadors and more than 10 My Green Lab Accredited Professionals on their team, can serve as the catalyst to empower labs toward sustainable excellence. Building a Sustainable Future Together Regardless of what you need, a partnership with an experienced environmental services provider can help you fully achieve your sustainability goals. With a suite of trained consultants, national reach, and backed by a team of qualified and dedicated onsite support staff, Triumvirate Environmental is well-equipped to support your lab’s journey towards sustainability. As our Accelerator Partner, Triumvirate Environmental has everything you need to succeed in your My Green Lab Certification journey. Our collaboration with Triumvirate Environmental underscores the importance of a comprehensive approach to sustainability. By leveraging the strengths of both My Green Lab and an environmental partner, labs can achieve their sustainability goals more effectively and efficiently. Together, we can make a significant impact on the environmental footprint of the scientific community. My Green Lab and our newly launched commercial subsidiary, Impact Laboratories, are proud to announce the appointment of Jennifer Edson as Chief Financial Officer (CFO)! With a distinguished background in finance and internal operations, Jennifer brings a wealth of experience to the My Green Lab and Impact Laboratories executive team. As CFO, Jennifer will provide crucial early-stage financial and operational leadership to accelerate their shared mission of bringing sustainability to science.

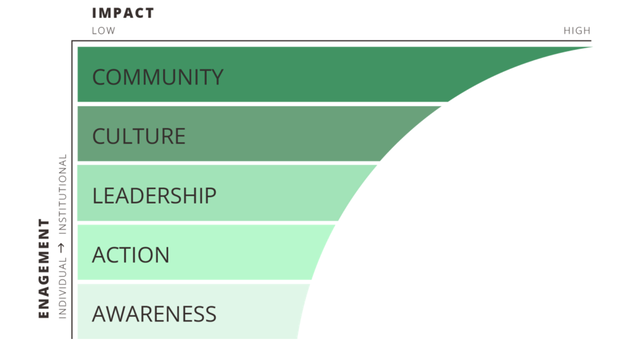

"Jennifer's depth of start-up finance expertise and proven executive leadership makes her an invaluable addition to our team," said James Connelly, CEO of My Green Lab. "Jennifer is one of the most respected start-up accounting leaders in the Pacific Northwest and her passion for developing scalable GAAP-compliant financial systems in a high-growth environment is the exact skill set we need to advance My Green Lab's and Impact Laboratories’ mission as we scale.” Jennifer’s career spans over three decades, during which she has garnered accolades for her adept leadership and problem-solving skills. As the former CFO of Plunk, an AI-driven real estate analytics company, and COO at Denali Founder Consulting, Jennifer has demonstrated her ability to navigate complex financial landscapes for early-stage technology companies while providing strategic executive leadership that fosters growth and innovation. "My Green Lab's dedication to innovation and sustainability resonates deeply with me,” said Jennifer. “The opportunity to merge my financial expertise with a commitment to environmental responsibility is both exciting and fulfilling. I am honored to join the team and help contribute to a more sustainable future within science.” As CFO, Jennifer will play a pivotal role in overseeing financial strategies and operations, ensuring alignment with My Green Lab's and Impact Laboratories’ mission and programs and accurate reporting to investors and stakeholders. “I am eager to collaborate with the talented team at My Green Lab that is already recognized as the global leader on sustainability in science. With $1.35 million in new equity funding received last month and at least another $1 million in the pipeline, we are poised for rapid growth,” added Jennifer. “Together, we can accelerate the transition to sustainable labs at a global scale." Jennifer holds a Bachelor of Business Administration in Accounting from the University of Iowa and is a licensed CPA in Washington State. Residing in the Pacific Northwest since 2007, she brings with her a deep appreciation for the environment and a commitment to promoting sustainable practices both personally and professionally. The celebration of Earth Day serves as a reminder for us to reflect on our relationship with the planet and the impact of our actions. Every facet of our lives intertwines with the environment, both personally and professionally. In the laboratory, where innovation and scientific advancement take center stage, our impact may often go unnoticed. This Earth Day, let’s collectively examine how our actions within the laboratory extend beyond its walls and commit to meaningful steps towards positive change. By building a culture of sustainability, and embracing the idea that our actions can, and should, change, we pave the way for a greener, healthier future. To capture the spirit of Earth Day, we've shared five actionable approaches aimed at fostering a culture of sustainability within laboratory settings. 1. The My Green Lab Theory of Change At My Green Lab, our goal is to empower individuals to contribute to a culture of change in their organization. In order to engage and inspire colleagues and those in your community to make sustainable change, it can be helpful to situate behavior within a “Theory of Change” framework. The Theory of Change begins with awareness. First, we must become aware that there is a problem and understand that we can behave differently. This awareness drives action – breaking old habits to make way for new behaviors. Through actionable pathways to learning and implementing sustainability best practices, you build the confidence to continue going further in making a difference. This confidence will allow you to take leadership of initiatives, inspiring others around you to follow in your footsteps. As more people begin to adopt new behaviors, these practices become the norm, creating a positive and lasting culture of sustainability. As this culture grows, sustainability practices become institutionalized through policies, procedures, and organization level goals. And a collection of organizations with sustainable lab cultures creates a global community of passionate and active sustainability champions that fundamentally shift the way science is conducted.

The strength of this approach lies in its accessibility; even if you don’t currently have institutional support for your sustainability ideas and initiatives, you can start anyway, with individual awareness, collective action, and leadership. Build the momentum that will result in cultural change in your lab and in the global community. By fostering momentum, you can drive cultural shifts within your laboratory and contribute to broader global change. 2. The Power of Community Community plays a pivotal role in driving sustainable action. Through shared experiences and collective efforts, individuals in and around the lab learn, grow, and hold each other accountable. Embrace the power of community by spreading awareness and sharing the knowledge you’ve learned with those around you. “Our hearts and minds can be more easily moved by those closest to us,” says My Green Lab’s Senior Programs Manager Christina Greever-Wilson. “This is why we shouldn’t be shy about sharing our own lab sustainability goals – and successes – with others in our network. For someone who is on the fence about sustainability, hearing from a friend or colleague in their own community about the ease of making sustainable actions can make a huge difference.” 3. Leadership and Communication Clear communication and regular engagement with stakeholders are crucial for embedding sustainability into the culture of your lab or organization. When thinking about and planning your lab’s sustainability journey, provide ample opportunity for input and feedback, especially from scientific teams, who often have valuable insights into resource consumption and can test new sustainable protocols and processes. By actively listening to stakeholder ideas, the entire community becomes invested in the sustainability process. Beyond adopting sustainable practices, leaders must actively engage stakeholders and foster a collaborative environment where everyone feels empowered to contribute to positive change. Regular communication channels, such as meetings, newsletters, or digital platforms, provide opportunities to celebrate successes, address challenges, and keep sustainability goals at the forefront of everyone's minds. Ultimately, by prioritizing transparent communication and inclusive leadership, laboratories can foster a culture where sustainability is embraced as a core value and integrated into everyday practices. 4. Small Yet Impactful Sustainability Practices Matter Seemingly small changes in laboratory operations can have a significant impact on sustainability. Take, for instance, the simple act of sharing printers among colleagues or setting up printers to default to double-sided, black-and-white mode. This not only reduces paper waste but also contributes to a cleaner laboratory environment by minimizing clutter. Does checking for leaky faucets sound too simple? It shouldn’t! Leaky faucets that drip once per second can waste 3,000 gallons of water per year. According to the US EPA, that’s enough water for more than 180 showers! Minor adjustments not only contribute to environmental conservation but also foster a culture of sustainability within the laboratory community, where every individual action counts towards a greener future. By emphasizing the importance of individual actions and illustrating the tangible benefits of sustainability practices, leaders can inspire a collective commitment to minimizing environmental footprints. Moreover, by highlighting the cumulative effect of these efforts, laboratories can underscore the significance of every contribution, no matter how modest, in advancing the goal of a greener future. 5. Planet vs. Plastics This year’s Earth Day theme is Planet vs. Plastics, with earthday.org calling for a 60% reduction in the production of all plastics by 2040. Without a doubt, plastic remains one of the most commonly discarded materials in laboratories. Plastic is everywhere in the lab, from tube racks and pipette tips to conical vials and filtration flasks, with the list constantly expanding as research and industries discover new applications for plastic. And while some of this plastic is necessary, there are ways to reduce and reuse, as well as considerations for a plastic to have a different end of life. Our team has put together a variety of resources to help you kickstart your waste reduction journey. Read our blog post on How to Reduce Waste in the Laboratory, or guest contributions like Sustainable Pipetting: Tips for Reducing Plastic Usage in the Lab and How To Kickstart Your Waste Reduction Journey. Additionally, those interested in a deeper dive into lab waste can sign up for My Green Lab’s Accredited Professional (AP) Program Module on Waste. Continuous Improvement While Earth Month is a significant time to reflect on how our actions impact the earth, it’s important to recognize that your journey doesn’t end here. The path towards a truly sustainable future requires a commitment to continuous improvement. By remaining vigilant, receptive to new ideas, and dedicated to refining your practices, we can build upon our successes and drive even greater positive change. Embrace the challenge of constant evolution, knowing that every step forward, no matter how small, brings us closer to a more sustainable tomorrow. Together, let's continue to communicate, educate, and inspire, ensuring that our laboratories not only lead the way in scientific discovery but also serve as beacons of environmental stewardship for generations to come. We're thrilled to spotlight Sven Duda, an accomplished member of the green labs community who is not only a dedicated My Green Lab Ambassador but has also helped the Chair of Applied and Molecular Microbiology in the Biotechnology Institute at the Technische Universität Berlin achieve My Green Lab Certification.

Sven, a research associate at Technische Universität Berlin and a My Green Lab Ambassador, is deeply committed to fostering a culture of sustainability. Through the My Green Lab Certification process, Sven and his colleagues at the Chair of Applied and Molecular Microbiology have enhanced their lab's sustainability practices. His commitment exemplifies the transformative potential of collective action and the power of small changes in driving meaningful progress towards a more sustainable future. Learn more about the Ambassador Program and My Green Lab Certification through Sven’s journey, detailed below. Please tell us a bit about yourself. My name is Sven Duda. I was born and raised in Berlin, Germany. I’m currently working at the Technische Universität Berlin as a research associate deeply involved both in my research project working with fungi and the implementation of sustainability measures within our laboratory and university. Apart from my academic pursuits, I’m also a passionate Touch Rugby player. In addition to my main roles of researching, assisting purchasing, and student supervision, I am an assigned sustainability manager. Together with my Applied and Molecular Microbiology department colleagues, we worked our best to achieve a My Green Lab Certification in November 2023. Let’s chat about your experience with My Green Lab Certification. Before launching the program, what challenges were your lab facing concerning lab sustainability and engagement? Before the certification process, we had implemented some sustainability practices, but there were challenges. For example, we share our resources with other departments at the Technische Universität Berlin. And while we are trained to use the devices and talk about the contamination risks beforehand, we did not have a good overview of which devices utilize which quantities of electricity, and there was no point of reference for what a kWh is and how much polluting potential this encased. This made our decisions on saving energy tough. Can you share a bit about your experience going through My Green Lab Certification – including what you learned and sustainability success stories within your lab? My experience through the My Green Lab Certification process was very encouraging. The progress report results from our baseline assessment shared clear instructions for sustainability best practices, databases to work with, and positive feedback on things that had been working. This report, along with the contact we had with the My Green Lab team personally, motivated me to go further and think of more sustainable measures to share with my colleagues and others from the Technische Universität Berlin. It really is the small things that can make a big difference. For example, the utilization of stickers to make colleagues aware of shutting down devices that don't take long to turn on (clean benches and their lights, vortexers, light switches on the hallways, etc.). Also, the utilization of outlet timers on water baths or drying ovens for a more effective usage of time and electricity. They are such an everyday tool at home, but we hadn’t thought about using them in the lab! The certification showed us how to think outside of the box and try ways to be more sustainable and be more responsible when researching and experimenting. Can you share any data that suggests improvement on sustainability parameters? By taking out 50% of our neon tubes from the hallway and disconnecting devices that we don't need on at night, we estimate that we have reduced electricity waste by at least 20% in comparison to before the certification process. In order to create a better overview of electricity usage in our department, more numbers and measurements are in preparation with the Occupational Health and Safety Services and Environmental Protection departments of the Technische Universität Berlin. What effect did the certification process have on the sustainability culture within your organization? We realized that the My Green Lab Certification is not only a sustainability certification, but also a great teamwork builder! The program drove me to start attending university events and department talks to share our experience with those who can profit from our work in developing science for our community in a sustainable way. What is the most interesting thing you learned while becoming a My Green Lab Ambassador? The My Green Lab Ambassador Program educated me on the basis of sustainability in a lab! Many of the things we do in the lab, even the good things, are done because they were written or decided years ago without re-checking their effectiveness. The Ambassador Program motivated me to talk openly with my colleagues about which sustainability measures we need to implement or improve. The most interesting thing I learned was that, as I mentioned before, small changes in the lab, as well as our perception, can make a big impact on our way of working and using resources. How has the My Green Lab Ambassador Program enriched your sustainability journey? The My Green Lab Ambassador Program enriched my and the Chair of Applied and Molecular Microbiology's sustainability journey by showing us that this is not a journey we need to do alone. It encouraged me to get other colleagues at the Technische Universität Berlin involved and help ‘activate’ them with the reason they began their careers in science: curiosity. My Green Lab is proud to announce the launch of our new commercial subsidiary, Impact Laboratories. Impact Laboratories will advance My Green Lab’s certification program through third-party verification. Our two organizations will work together to accelerate progress on our shared mission of building a global culture of sustainability in science. My Green Lab CEO, James Connelly, says, “This is a pivotal moment in the continued growth and evolution of My Green Lab. The introduction of third-party verification ensures our certification adopts international best practice and provides verified impact, giving scientists and organizations yet another reason to embrace the world’s most trusted green lab certification.” “As we scale our efforts around the world, it’s vital that we constantly seek ways to better support our community, measure our impact, and ensure the continued integrity of our programs. Introducing third-party verification will help the entire scientific community by accelerating the journey to lab sustainability at a global scale,” continues Connelly. Impact Laboratories will help deliver more resources, enterprise scale software tools and funding to help My Green Lab better support its many vital programs and build an even more successful community-driven movement. The increased support will include more in-depth research, resources, community building and educational events, and more substantial discounting for academic labs through an organization subscription model. The programs, tools and education services supported by My Green Lab include:

“My Green Lab Certification is a key way in which we are accelerating emissions reduction in healthcare R&D and instilling a culture of sustainability at AstraZeneca. We are encouraged to see My Green Lab raise the bar yet again and align with international best practice by providing third-party verification to enhance the rigor of this powerful certification platform.” — Penny James, COO Biopharmaceuticals, AstraZeneca, and My Green Lab Board Member “Quality, integrity, and community are at the heart of My Green Lab’s mission. We are constantly working to strengthen our programs and enhance our impact. Third-party verification is the next step that helps drive action and impact in one of the industry’s most challenging arenas: labs and lab supply chains.” — Jeffrey Whitford, Vice President, Sustainability and Social Business Innovation, MilliporeSigma, the US and Canada Life Science business of Merck KGaA, Darmstadt, Germany, and My Green Lab Board Member “My Green Lab is helping to transform the entire academic scientific community through their programs and tools, and third-party certification is an important next step to ensure impact. We have certified over 200 labs at UAB and we are excited to take advantage of the new resources and tools that Impact Laboratories will be providing the academic community.” — Nick Ciancio, Sustainability Coordinator, University of Alabama at Birmingham, and My Green Lab Certification Steering Committee member |

Sign Up for Our Newsletter! |

Contact UsCopyright 2013-2024 My Green Lab®, all rights reserved.

About My Green LabMy Green Lab® is a 501c3 non-profit organization.

All gifts are tax deductible in accordance with IRS regulations. |