Scientists and procurement specialists are placing greater emphasis on environmentally responsible purchasing decisions, and manufacturers are stepping up to meet the demand. For KNAUER, sustainability is not a new trend–it’s a tenet of the organization that is built into its processes and products. This commitment has earned KNAUER’s HPLC systems the lowest Environmental Impact Factor (EIF) score in the My Green Lab® ACT® Ecolabel database (as of January 2025).

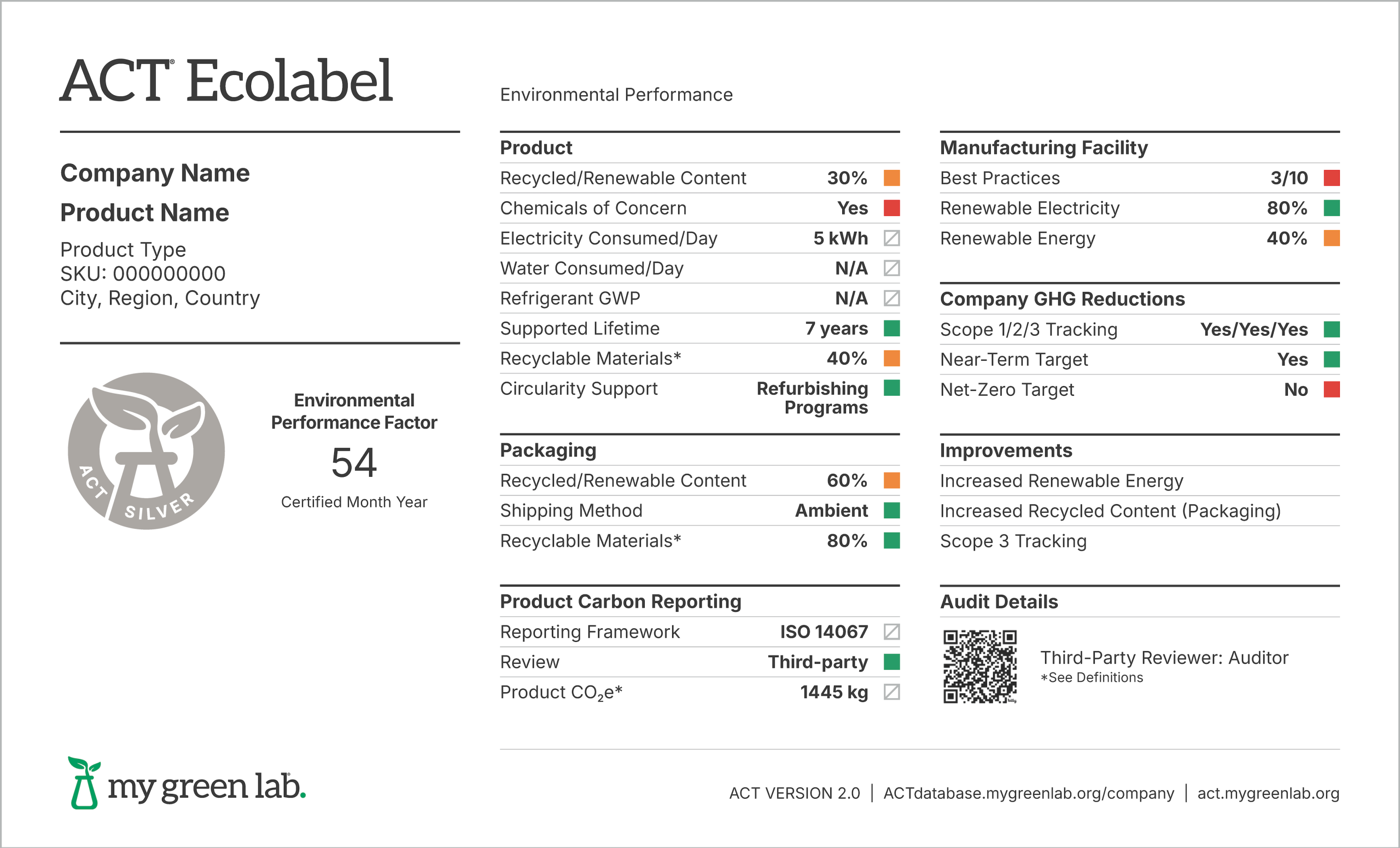

The ACT Ecolabel provides third-party verified information about the environmental impact of laboratory products, helping drive smarter and more sustainable purchasing. It enables manufacturers to demonstrate Accountability, Consistency, and Transparency (ACT) by evaluating materials, manufacturing process, recyclability, energy and water consumption, durability, and manufacturing location. With over 2,000 products currently listed, the ACT database helps labs and procurement specialists make informed, sustainability-aligned choices while motivating manufacturers to enhance their products’ environmental performance.

Laying the foundation: KNAUER’s sustainability goals

KNAUER’s journey toward achieving ACT certification began with a strong foundation in sustainability practices. “We are proud to be part of the UN Global Compact and to have ISO 14001:2015 certification,” said Clemens Buncher, Senior Quality & Environmental Manager. “Our Quality Assurance (QA) department, which I am a part of, also handles certification and reporting activities for sustainability and quality. The ACT Ecolabel perfectly fit into the scope of our activities and provided opportunities for improvement.”

When KNAUER decided to pursue the ACT Ecolabel, their goal was to validate and enhance their sustainability efforts while gaining deeper insights into the environmental impact of their products. Soheil Shayesteh, Head of Service and Support, emphasized KNAUER’s commitment to longevity and customer satisfaction: “I see it as the responsibility of manufacturers to develop and produce clean and long-lasting products. This means minimizing the negative effect on the environment while at the same time providing the customer with excellent products.”

“Our aim was to enhance our offerings and confirm that our efforts lead to positive outcomes,” said Buncher. “With the ACT program, we were able to achieve all of these goals for our HPLC systems. My Green Lab provided us with a standardized system to evaluate the sustainability of our products and verify the results to enhance customer trust.”

Navigating the certification process

The auditing process assessed key EIF categories, including materials, manufacturing, packaging, user impact, and end-of-life. Developed with input from industry experts and external stakeholders, these criteria were independently audited by My Green Lab’s collaborator SMS Collaborative, LLC (SMSC). Ultimately, this comprehensive assessment determined the information and EIF score shown on KNAUER’s ACT Ecolabel.

KNAUER’s HPLC systems received the lowest EIF score currently in the ACT database. Throughout their journey to achieve the ACT Ecolabel, KNAUER worked closely with My Green Lab to assess the environmental impact of their HPLC systems, appointing an internal project manager from their QA department to lead the effort.

“Resources from other departments were made available upon request and within reason to support and ensure the progress of the project. New test equipment was made available and our evaluation team in the lab was also involved,” shared Buncher. Collaboration across teams was vital to meeting the rigorous certification criteria. “The longevity and reparability of our products greatly contributed to our score,” noted Buncher. “We were also happy with the measured power consumption of the systems.”

The certification highlighted areas for improvement, as Buncher explained: “The energy consumption of KNAUER products has received more attention through the certification process. The weight of individual components was also highlighted, strengthening our efforts to reduce this in future developments.” He added, “This point is now included in the standard requirement specification for KNAUER products.”

“To see the final results was a very special moment for us,” said Dr. Christian Benkhäuser, Head of Research & Development. “It showed us that we are doing the right things, and it helps us to go this path even further and improve.”

Sustainability as a catalyst for innovation

The ACT Ecolabel’s in-depth evaluation not only validated KNAUER’s sustainability efforts but also spurred further innovation. “In the past, we didn’t focus on using recycled materials,” said Dr. Benkhäuser. “During the ACT certification process, this was a topic that came up, and we started to evaluate possibilities to exchange materials to the recycled versions.”

Dr. Benkhäuser also noted several environmental topics that are now in their development process as a result of the ACT Ecolabel: “Can we use other/less material? How can we make the product more efficient (less material, less energy needed)? How can the device be serviced? That’s maybe the most important point for us: Every device can be serviced very easily, we try to keep the assembly groups small, so that just a few materials are needed to repair.”

Buncher elaborates: “The certification process established a new standard for orientating our product development and management processes, while also reminding us of the importance of sustainability in our product decisions.”

Empowering customers through transparency

The ACT Ecolabel simplifies complex environmental data, empowering laboratories to make informed and sustainable purchasing decisions that align with their environmental goals. “The ACT Ecolabel helps to bring companies and customers with the same philosophy together,” said Dr. Benkhäuser. “It is nice to make it easier for customers to find products that match their sustainability philosophy.”

One of the main goals of the ACT program is to provide laboratories with a database of third-party verified products, simplifying the process of choosing more sustainable products. “The program allows us to quantify our efforts and enables our customers to check our products for sustainability in comparison with competitors. Our sustainable programs and projects which lead to more sustainable products are made more visible,” said Buncher.

Leading the way: a model for sustainability

The ACT Ecolabel enables KNAUER to align its sustainability goals with broader industry benchmarks. “KNAUER wants to provide long-lasting products and service them for as long as possible,” said Shayesteh. “The certification fits into achieving this goal, as it is important to get an external view and to compare with other manufacturers,”

KNAUER’s packaging further supports sustainability, with 80% recycled materials and take-back programs in the US, EU, and UK. These efforts, paired with energy-efficient production and life cycle assessments, demonstrate KNAUER’s dedication to minimizing environmental impact.

Raj Patey, My Green Lab’s Business Development Director, highlighted KNAUER’s industry leadership: “Their exceptional EIF score sets a benchmark for the industry. We’re proud to support KNAUER in this journey toward greater accountability and transparency in lab product sustainability.”

KNAUER’s commitment to sustainability showcases how manufacturers can lead the way in responsible product development, setting a standard for others in the industry to follow. Through continuous improvement and innovation, they are helping shape a greener future for laboratory science.

“There is a lot to think about and to take into account when developing, producing, and maintaining sustainable products,” said Kate Monks, Head of Quality and Regulatory. “We’re proud of our ACT Ecolabel and the excellent score we got for the HPLC systems.”

Want to learn more or adopt the ACT program? Browse our website or reach out to us at businessdevelopment@impactlaboratories.com.